Softgel Manufacturer

Your premier softgels manufacturer

As a premier softgels manufacturer, we provide custom, high-quality softgel solutions with precise manufacturing and optimal ingredient absorption. Our end-to-end services cover formulation, production, and packaging, ensuring consistency and reliability.

What are Softgels?

Softgels are a type of oral capsule made from a gelatin-based shell that is soft, flexible, and easy to swallow. They are typically filled with liquid ingredients, such as oils, vitamins, or herbal extracts, allowing for more efficient absorption of active ingredients compared to tablets or traditional capsules. Softgels are popular for delivering supplements, medications, or nutrients in a convenient, tasteless, and precise dosage form.

Why Softgels?

Softgels offer superior absorption, faster effectiveness, and precise dosage control. Their easy-to-swallow design and tasteless, mess-free format enhance consumer experience. Ideal for encapsulating oils and sensitive ingredients, softgels ensure high-quality, targeted delivery of health supplements.

Benefits of Softgels

- Easier to swallow: Their smooth, gel-like texture makes softgels more comfortable to ingest, especially for those who have difficulty swallowing pills.

- Better absorption: The liquid form inside softgels is absorbed more quickly and efficiently in the digestive system compared to tablets or hard capsules.

- Precise dosage: Softgels provide an exact dosage of the active ingredient, ensuring consistency in each serving.

- No aftertaste: The gelatin shell masks the taste of unpleasant ingredients, making softgels more palatable.

- Extended shelf life: Softgels are more resistant to moisture and air, helping to preserve the potency and freshness of the ingredients for longer periods.

Features & Benefits

What you can expect when you work with us

Global Leadership & Innovation

We aim to be a leading health supplement manufacturer, providing innovative, high-quality products that enhance health and well-being globally.

Customized & Private-Label Solutions

We specialize in offering tailored, private-label solutions to meet the specific needs of brands, ensuring precise, high-quality products that align with your vision.

Integrity & Sustainability

Our commitment to integrity and sustainability ensures that we deliver products that meet both ethical standards and consumer demands for eco-friendly solutions.

Cutting-Edge Technology & Quality Control

By leveraging advanced technology and stringent quality control processes, we ensure that every softgel meets international standards for safety, effectiveness, and consistency.

Collaborative Partnerships

We prioritize building lasting, collaborative relationships, empowering our clients to succeed in global markets with trusted, personalized products.

Healthier Future

Our mission focuses on creating a healthier future for all by providing high-quality, effective supplements that improve consumer well-being worldwide.

Softgel Manufacturing Process

Formulation Development

The active ingredients (liquids, powders, oils, etc.) are carefully selected and blended to create a stable and effective formulation. The formulation is designed to meet the specific needs of the product (e.g., vitamins, supplements, or pharmaceuticals).

Gelatin Shell Preparation

A gelatin mixture (or plant-based alternative for vegan softgels) is prepared by heating gelatin, plasticizers, water, and other excipients to create a smooth, pliable dough-like consistency for the shell.

Encapsulation

The prepared formulation is filled into softgel shells using specialized machinery. This is done in two ways:

- Liquid Filling: The formulation is encapsulated in a gelatin shell and sealed.

- Powder Filling: A softgel shell is used to encase powdered ingredients, often with a small amount of liquid to aid in sealing.

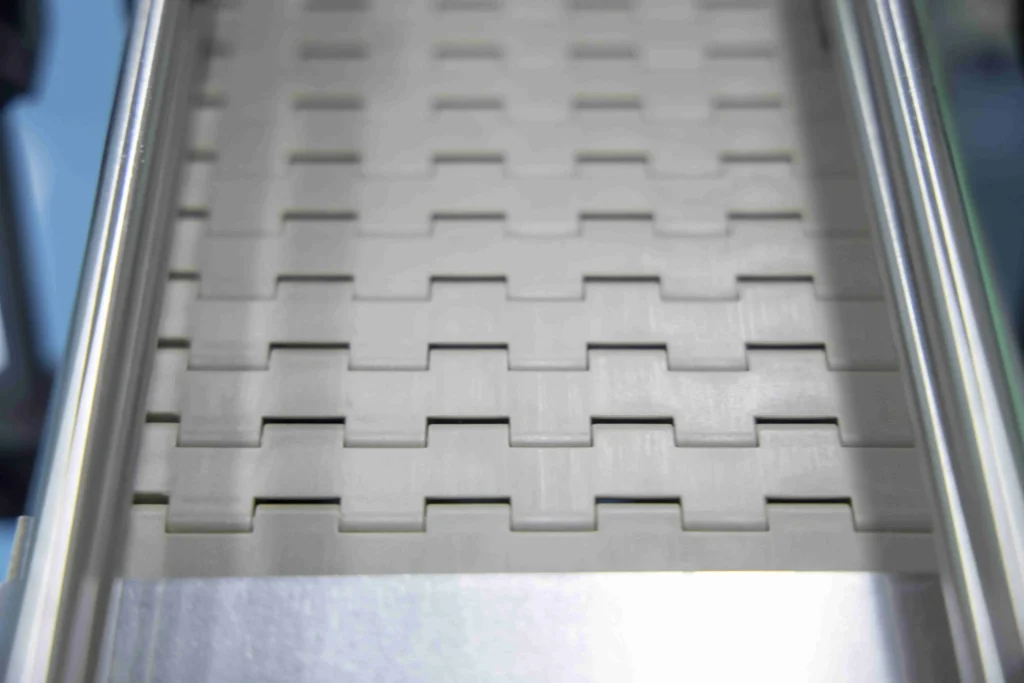

Softgel Formation

The gelatin is extruded into ribbons, which are then cut into individual softgel shapes. The capsules are formed using a rotary die system, which molds and seals the softgels.

Sealing

The softgels are sealed to prevent leakage. This is done by carefully applying pressure, heat, and sometimes vacuum to ensure the shell is properly closed around the filling.

Drying

The softgels are then dried to remove excess moisture, which helps maintain their stability and prevents the shells from becoming too soft or sticky.

Polishing

Once dried, the softgels are polished to give them a smooth, shiny surface. This is often done with a food-grade wax or other coating material to enhance appearance and ease of swallowing.

Quality Control

Softgels undergo rigorous quality control checks, including testing for weight, size, seal integrity, and uniformity of the active ingredients. This ensures the final product meets regulatory and industry standards.

Packaging

After passing quality control, the softgels are packaged into bottles, blisters, or other packaging formats, depending on the client’s requirements. Packaging is done in a controlled environment to avoid contamination.

Final Inspection & Distribution

The final product is inspected one last time for any defects before being shipped out for distribution. This ensures that only the highest quality softgels reach the market.

Elevate Your Brand With Wellzencare

Wellzencare specializes in affordable custom gummy vitamin manufacturing with low minimum order quantities. Our R&D team works closely with clients to develop science-based formulations for high-quality dietary supplements.

Save Your Time & Cost Your valuable supplement partner

Manufacture

Services

- Package Design

- FAQs

© 2025 All Rights Reserved.